MGB Bike Rack

As an avid cyclist and owner of a diminutive 1969 MGB roadster, I was frequently faced with the problem of transporting my race bike to and from the ultramarathon cycling events I partcipated in. My initial solution to the problem was to place my bike behind the MGB’s two front seats. However, this entailed the removal of its front and rear wheels, chain, and derailleur–a very time-consuming practice. A better solution was needed.

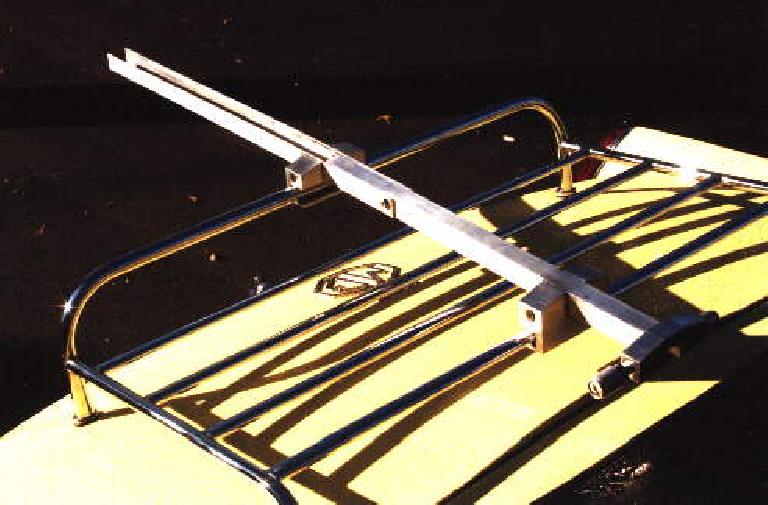

Typical bicycle carriers on the market either attached to a vehicle’s roof or strapped onto the car’s trunklid. Since my car is a convertible, the former type was not an option. I also had qualms about a bulky bicycle carrier resting on the shiny paint of my classic automobile. Hence, this prototype luggage rack-mounted bicycle carrier was born.

This MGB bike rack was actually my ME103 (“Design & Manufacturing”) project at Stanford University the winter quarter of 1996. It is designed for my road bike but I have used it with my mountain bike as well. I think I have gotten about 6000 miles of use out of it so far.

Objectives & Requirements

To design and manufacture a bicycle rack that met the following criteria:

- Quick set-up time

- Does not touch vehicle’s paint

- Stable in crosswinds and heavy cornering

- Lockable

- Compact and easily stored

- Under $100 in parts and materials

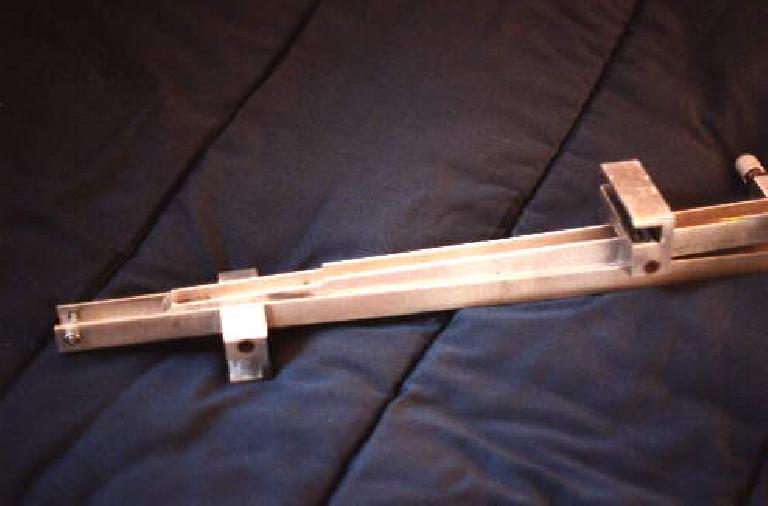

The Final Product

Setup is a six-step process that takes two or three minutes:

- Unfold bicycle carrier

- Clamp onto luggage rack

- Attach single bolt through the two channel-section members using two 7/16″ wrenches

- Take off front wheel of bicycle

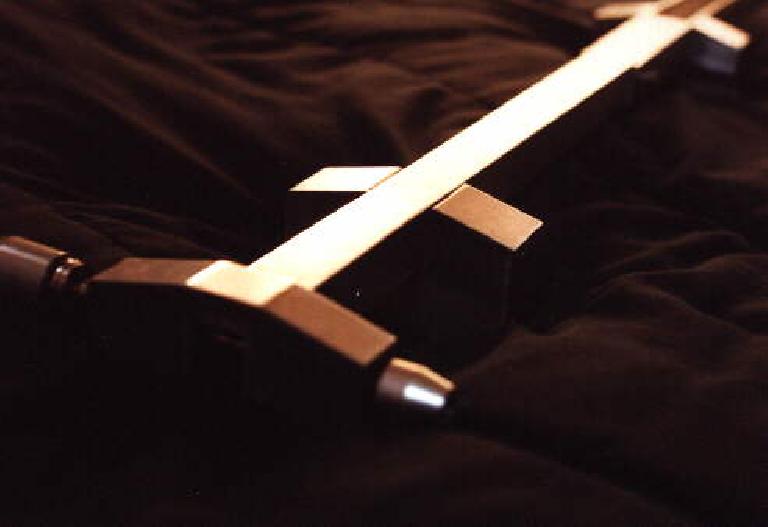

- Attach and lock bicycle fork to the for mount’s lockable Cyclox skewer. The rear wheel of bicycle will be resting in the rear channel-section member.

- Securing bungee cords from bicycle seat post to MGB luggage rack to provide additional stability in cornering and strong crosswinds

The advantages of the bicycle carrier are as follows:

- Extremely lightweight: under 5 pounds

- Foldable; very compact

- One-bolt design minimizes setup time

- Total cost: $58 ($33 for 6 lbs. of raw aluminum and $25 for the Cyclox locking skewer)

- Attaches to the luggage rack, safely away from the car’s paint

Engineering Drawings

- Here are some basic drawings (PDF, 43 KB) I whipped up in college circa 1996, before I became a Professional Engineer. Some dimensions may be missing but most can be inferred.

- A more professional assembly drawing (PDF, 404 KB) which I did more recently in SolidWorks.

It Worked With Mountain Bikes Too

The U-channel I selected was wide enough for a road bike tire, but not for a mountain bike one.

The bicycle carrier still worked with MTBs, however. Instead of sitting in the U-channel, the rear MTB tire would sit on it.

For security, I wrapped a velcro strap around the MTB rim and bicycle carrier, where the tire sat on the U-channel section.

There are 4 comments.

Hi There,

Looking for exactly this for my MGB Roadster 1972.

How can I get hold of one ASAP in time for my 5 day cycling trip on 12th June '23?

Thank you inn advance for any help you can give me.

Hi Brian. There's only one example of my MGB bike rack in the world since it was a design and manufacturing project I did in college in 1996.

For your bike trip, consider one of the universal trunk-mounted racks that use straps. Those racks rest on the car bodywork and are hence not as good. But they could work in a pinch.

I hope you find something that can work. Have a great cycling trip in June!

I installed a trailer hitch, and bought a bike rack to fit. Carries two and wheels don't need to come off.

That is the best off-the-shelf solution as long as the car owner doesn't mind installing a hitch.